Handheld faeba laser tjheseletsa tšepe bakeng sa aluminium tšepe e sa hloekang

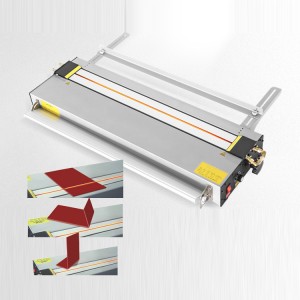

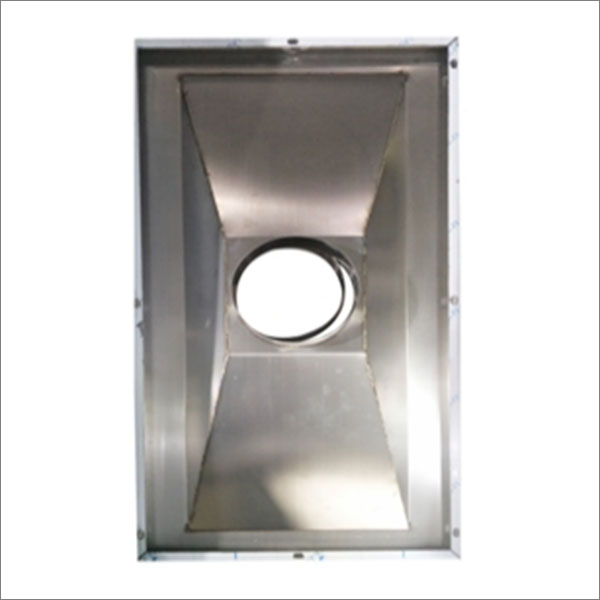

Mochini o ts'oarellang ka letsoho oa fiber laser, o sebelisa jenereithara ea morao-rao ea laser.E na le hlooho e sisinyehang le mochini o tlatsang mohala.Mechini e bonahala ho indasteri ea lisebelisoa tsa laser, e tlatsa sekheo sa tjheseletsa e ts'oaroang ka letsoho.E na le melemo ea ts'ebetso e bonolo, beam e ntle ea welding le lebelo le potlakileng la welding.Welding ka aluminium e tšesaane, lakane ea tšepe e sa hloekang, lakane ea tšepe, lakane e entsoeng ka masenke le lisebelisoa tse ling tsa tšepe li ka nkela sebaka sa khale sa arc welding, welding ea motlakase le lits'ebetso tse ling.Mochini oa welding oa letsoho oa laser o ka sebelisoa haholo ka likhabinete, kichineng, litepising, lifti, liraka, lionto, mamati a tšepe e sa hloekang le lifensetere tsa tšireletso, mabokose a kabo, ntlo ea tšepe e sa hloekang le liindasteri tse ling tse rarahaneng le ts'ebetso e sa tloaelehang ea welding.

| 1 | Moetso oa mochini | Mochini o ts'oaretsoeng ka letsoho oa fiber laser welding |

| 2 | matla a laser | 1000W, 1500W, 2000W, 3000W |

| 3 | bolelele ba maqhubu a laser | 1070 NM |

| 4 | Bolelele ba fiber | Standard10M Maximum 15M |

| 5 | mokhoa oa ho sebetsa | Continuation/ Ketsetsano |

| 6 | Lebelo la lebelo la welding | 0~120 mm/s |

| 7 | Chiller e phodileng | Sehatsetsi sa metsi sa indasteri |

| 8 | Boemo ba mocheso oa tikoloho ea ho sebetsa | 15 ~ 35 ℃ |

| 9 | Sebaka sa mongobo ea tikoloho ea mosebetsi | <70%Ha ho condensation |

| 10 | Likhothaletso tsa botenya ba welding | 0.5-3 limilimithara |

| 11 | Litlhoko tsa lekhalo la welding | ≤0.5mm |

| 12 | motlakase o sebetsang | 220 V |

E ka sebelisoa haholo lik'haboteng, kichineng, lifti ea litepisi, lishelefong, ontong, lemati la tšepe le fensetere, lebokose la kabo, ntlo ea tšepe e sa hloekang le liindasteri tse ling tse rarahaneng le lits'ebetso tse sa tloaelehang tsa welding.

Lebelo la tjheseletsa ke makhetlo a 2-10 ka potlako ho feta tjheseletsa ea setso.Mochini o le mong o ka boloka bonyane li-welders tse 2 ka selemo.

Ho chesoa ka laser

Tloaelo ea ho cheselletsa

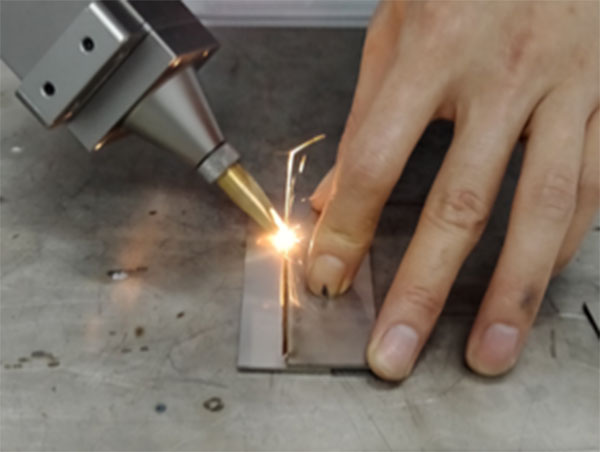

► Ts'ebetso e bonolo, 'me hoa khoneha ho kena mosebetsing ntle le lengolo la mosebetsi,' me sehlahisoa se setle se ka chesetsoa ntle le mosuoe.

Ho tjheseletsa fillet, welding e otlolohileng

Ho roka tjheseletsa

Ho tjheseletsa ka holim'a overlay

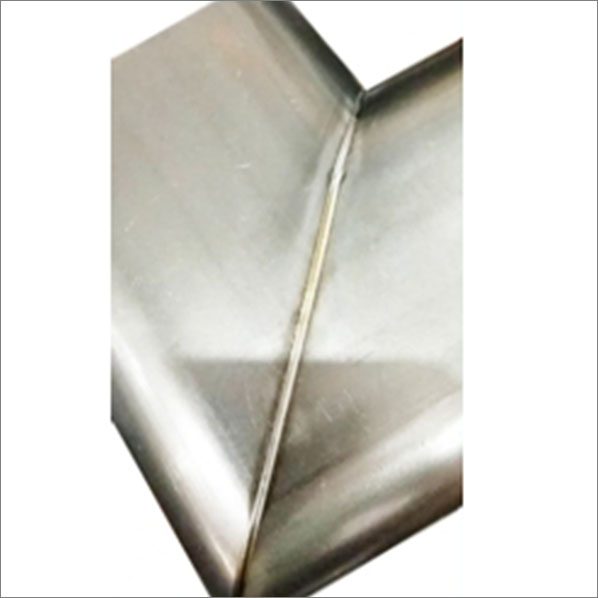

The weld seam e boreleli ebile e ntle, e fokotsa ts'ebetso e latelang ea ho sila, e boloka nako le litšenyehelo.

Ha ho na lebadi la welding

Weld e ntle

Ha ho na deformation ea workpiece

Ea itsoetseng peleWobble tjheseletsa hlooho compensates bakeng sa go tlhoka mesola ea laser tjheseletsa letheba nyenyane, atolosa ho mamella mefuta e fapaneng ya likarolo machined le bophara tjheseletsa, 'me fumana molemo tjheseletsa sebopeho.

The workpiece tjheseletsa ha e na deformation, ha ho tjheseletsaleqeba, 'me tjheseletso e tiile.

Laser welding e na le lisebelisoa tse fokolang le bophelo bo bolelele.

E bolokehileng hape e baballang tikoloho.